Perfect Harmony

While adopting innovative and creative solutions tailored to the specific needs of our customers as the basic principle of flexible production understanding, with our own know-how licenses and technologies, according to ADR-EN 13094 legislation, geographical region to be served by the climate and road conditions, carbon steel and alloyed aluminium materials, in accordance with design calculations, cylindrical section, large volume range, filling up from the top and bottom, appropriate to the LGBF tank code and hierarchy, can carry up from one to five partition of the dangerous substances in ADR Class-3, Truck-mounted Cylindrical Tanker capable of evacuation to the flow and discharged; perfect fit with the truck manufacturer's superstructure instructions and truck chassis in different configurations.

2.500 ~ 27.500 Lt.

Volume Range

1 ~5

Number of Compartments

-20 ~ +50 °C

Design Temperature

0,5 Bar

Design Pressure

LGBF

Tank Code

Strong Image

Add a solid image to its users with its experience from past to present, trustworthy certification processes and gained profit.

Modular Volume

Offer modular solutions for the trucks’ frame in different configurations with its alternative designs in wide range volume.

Difference Is Its Style

It creates a difference in style according to its own position and visual aesthetic.

Performance Needs Source

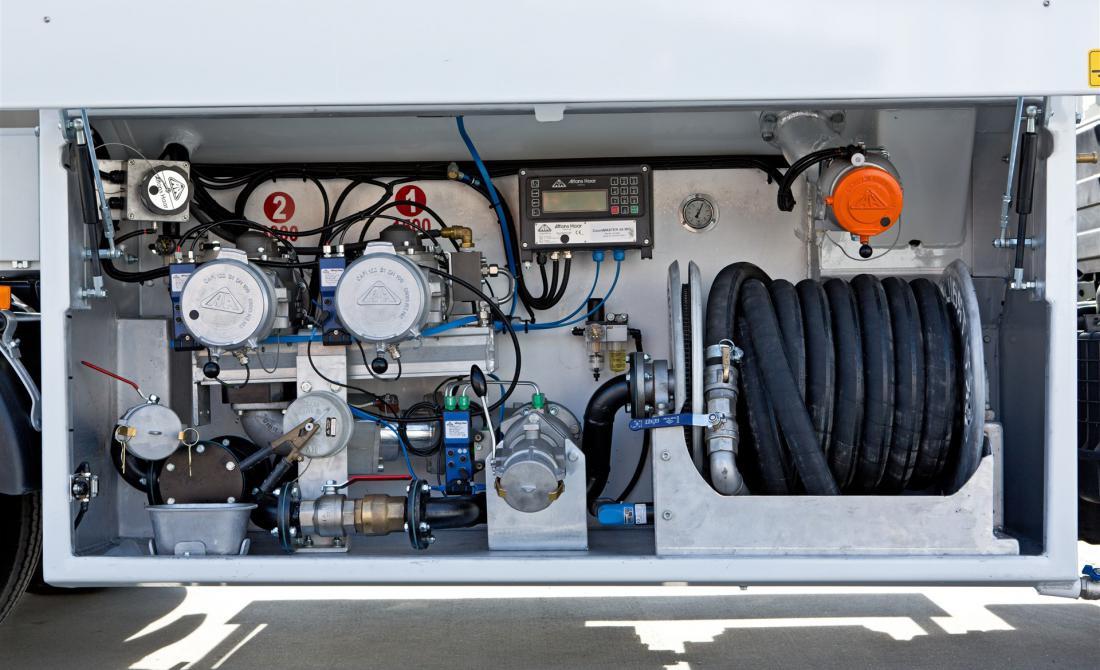

Durable body structure together with superior production technology and premium equipment turns the long lifetime into profit.OUTSTANDING FEATURES

Provides ease of use, safety and automatically locks the brake system.

Protect armatures against possible rollover and impact.

The equipment on the manhole cover is protected against seasonal weather conditions (rain, snow, sun, dust)

At the bottom of the tank, it provides full discharge of the product.

Provides mobility and ergonomic handling even in the narrow area

Provides full and secure supervision by national and international up-to-date legislative compliance and expert team.

Safe, smooth surface and unique body structure.

The least number of (T) joints provide high strength and long life.

Minimizes welding faults on the body due to tension and human factors, prevents product mix between compartments and secures against impact

Provides surface gloss in varnish quality.

Perfect fit between body and chassis under all kinds of road conditions, increase strength, reduce tension by distributing coming to the body force.

Increases body strength at chassis joints, reduces tension effect, provides unity of body.