High Angle

Tipping Silo Semi Trailer that is designed according to the European Pressure Vessels Regulation and customer demands with our own know-how license and production technology, fully conforming to ADR regulations, CE conformity approval for dangerous powders and granules transportation, can be made of aluminium alloy material with wide volume range, geometric structure for quick and easy discharge, single rear discharge alternatives; proves being intelligent investment with ’’High Angle’’, full and quick discharge capability of materials carried in different contents while being produced with continuous high performance robotic welding technology. Its reputation goes over the boundaries with its unique design, safe and long life structure that raises the standards.

40 ~ 87 m³

Volume Range

Single

Discharge Funnel

-40 ~ +80 °C

Design Temperature

0,5 ~ 3 Bar

Design Pressure

Power on the Top

Put its users over the top with its advantages, long life and powerful structure designed especially according to the customers’ expectations and needs for the transportation of food and industrial powder granules.

Modular Options

Options of special designed alternative volume, discharge systems and equipment; sort out your job.

Show of Strength

Its style of unique body design, original stand and visual aesthetic against compeers makes it more attractive.

Safe Lightness

We do not underestimate the weight! Carry out the dynamic loads at high volume under the heavy duty conditions with safe weight optimization and without compromising of the ergonomic driving.

Performance Needs Source

Durable body structure together with superior production technology and premium equipment turns the long lifetime into profit.OUTSTANDING FEATURES

Provides ease of use, safety and automatically locks the brake system

Prevents the material from staying inside and provides fast discharging, efficient use of air

Provides safe pressure control

Provides ergonomic, easily accessible, controlled and fast response

Pneumatic controlled, ergonomic, interceptible

Safe, smooth surface and unique body structure

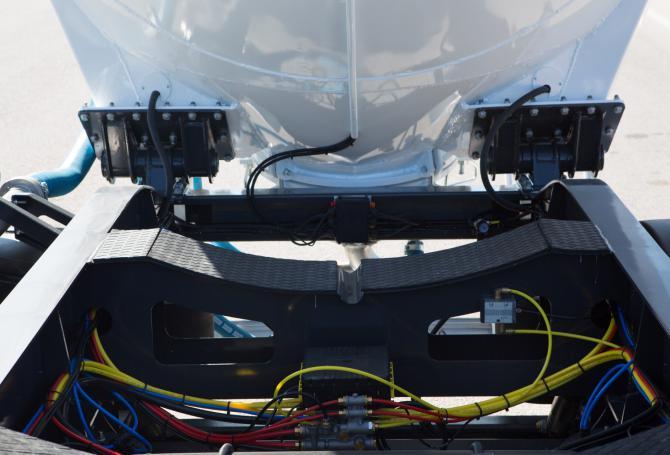

Minimizes welding faults on the body due to tension and human factors and secures against impact

The least number of (T) joints provide high strength and longlife

Provides surface gloss in varnish quality

CE certificated, safe, national international current legislation compliance

Vibration absorber, Light and Strong

National and International current legislation compliance

Prevents complexity on installation cables, provides serviceability