Traditional Angle

According to the European Pressure Vessels Regulation and the requirement to have CE conformity approval, with our own know-how license and production technology, we are able to produce carbon steel materials with thicknesses suitable for design calculations, V-type cut, geometric structure provides quick and easy discharge, single output, side and rear discharge alternatives, V Type Nontipping Silo Trailer- Semi Trailer; while being produced by continuous high-performance robotics welding technology, safe structure and traditional habits for those who do not want to give up their habits, with the traditional angle, its reputation exceeds the boundaries.

30 ~ 37 m³

Volume Range

Single

Discharge Funnel

-40 ~ +80 °C

Design Temperature

0,5 ~ 3 Bar

Design Pressure

Solid Background

The unchanging line from the past to the present day maintains its value for its users with strong stand, trustworthy certification processes.

Challenging Solutions

The geographical region it serves will facilitate the challenge under severe conditions with its structure specially designed for the changing conditions of the climate and roads.

Classic Style

It defies the years with its unique stance, visual aesthetics and unconventional classical style.

Performance Needs Source

Durable body structure, superior production technology and premium equipment, turn into the long lifetime to income.OUTSTANDING FEATURES

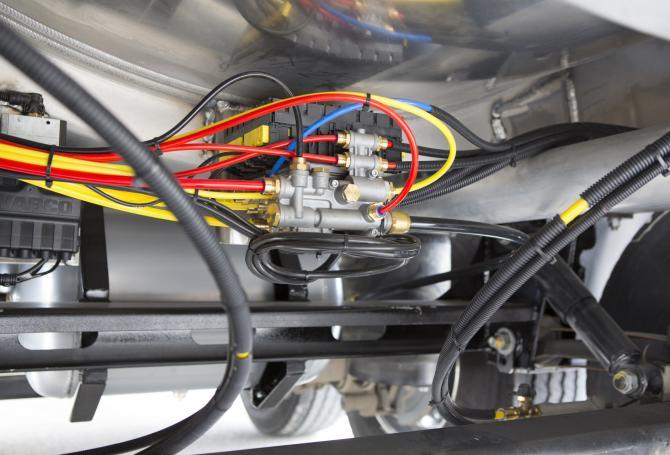

It provides ease of use, safety and automatically locks the brake system

Camlock provides quick and easy intervention against clogging with the connection and provides easy cleaning for the body

Pneumatic controlled, ergonomic, interceptible

Vibration damping, Light, Strength

Provides safe pressure control

Ergonomic, easy accessible, controlled and rapid intervention

CE and certified, safe, national international current legislation compliance

Minimizes welding faults on the body due to tension and human factors are secures against impact

Provides surface gloss in varnish quality

Perfect fit between body and chassis under all kinds of road conditions, increase strength, reduce tension by distributing force to the body

National and International current legislation compliance

Prevents complexity on installation cables, provides serviceability