Shape Of The Water

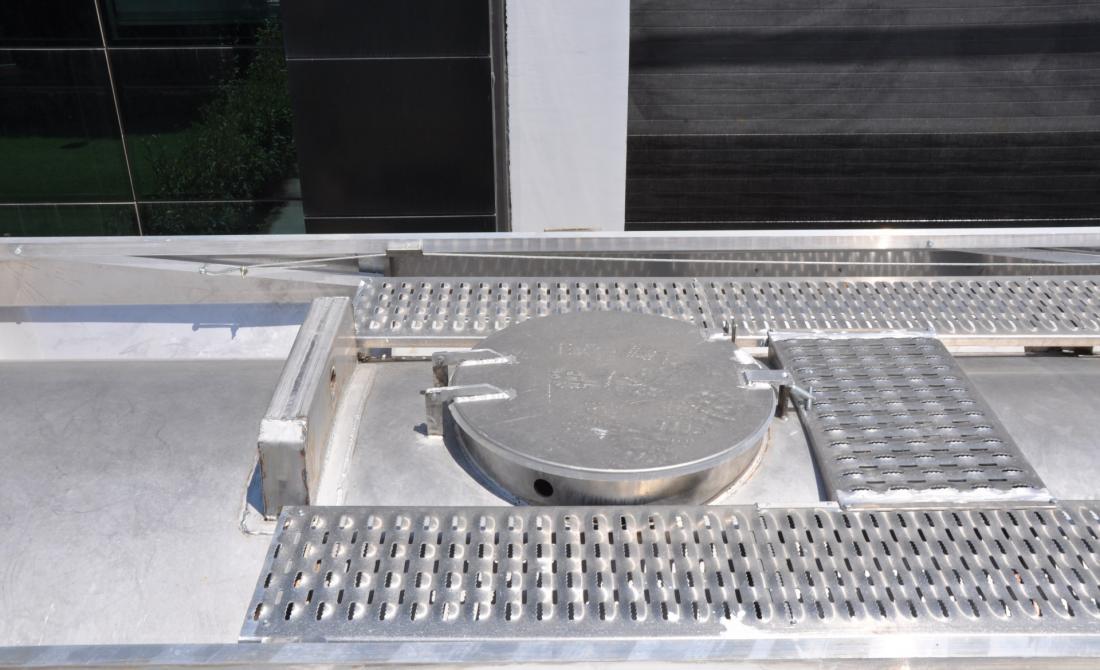

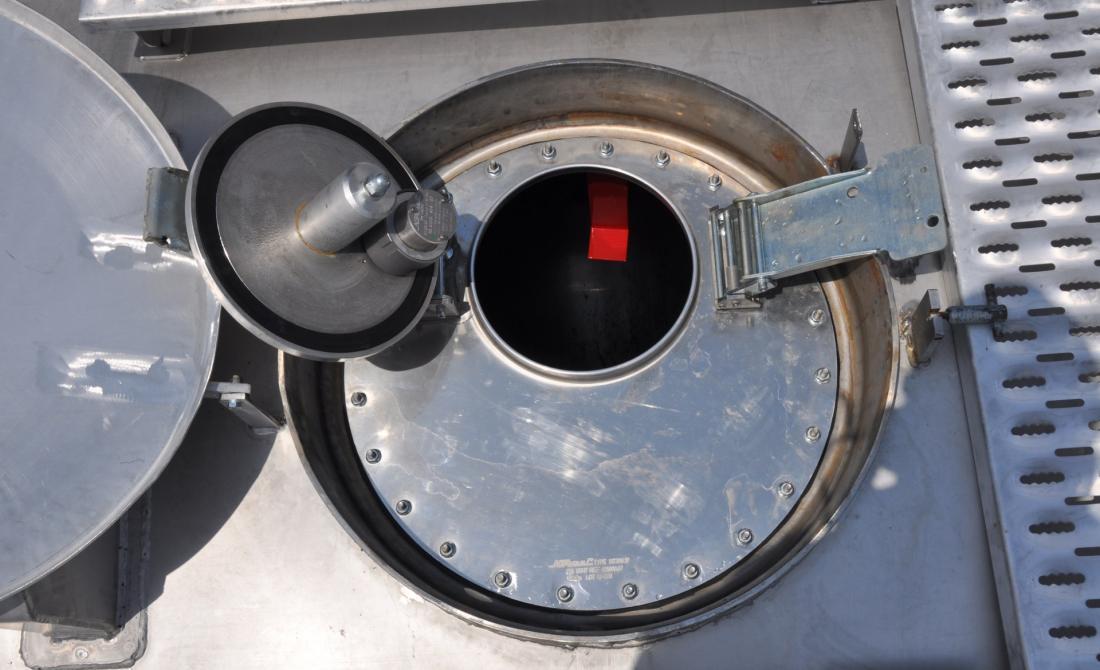

While adopting innovative and creative solutions tailored to the specific needs of our customers as the basic principle of flexible production understanding, our own know-how license is based on the geographical region and the technologies, and according to the region’s climate road conditions where we will serve- carbon steel for use water, stainless steel materials for drinking water in thicknesses suitable for design calculations, different geometric cross sections, large volumes, Water Tanker Semi Trailer which can be filled from top to bottom and can be transported one or three chambers, powered and dischared to the flow; (T) point and the longest weld seam technology, which is made up from seamless pieces in the main body structure andshape of the water it carries takes the form of unique body structure, it challenges both roads and years.

26.000 ~ 32.000 Lt.

Volume Range

1 ~3

Number of Compartments

-20 ~ +50 °C

Design Temperature

0,5 Bar

Design Pressure

Water is the future

Designed specifically for specific needs, drinking and industrial purposes, our water tankers offer added value to their users in the future with the advantages and long life.

Modular Options

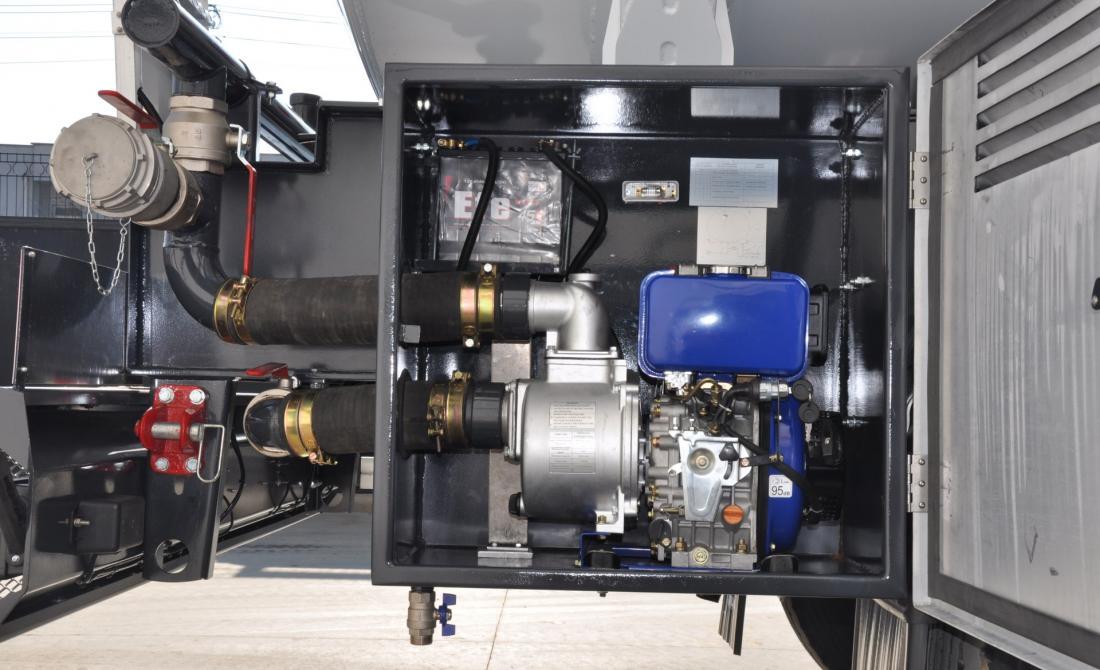

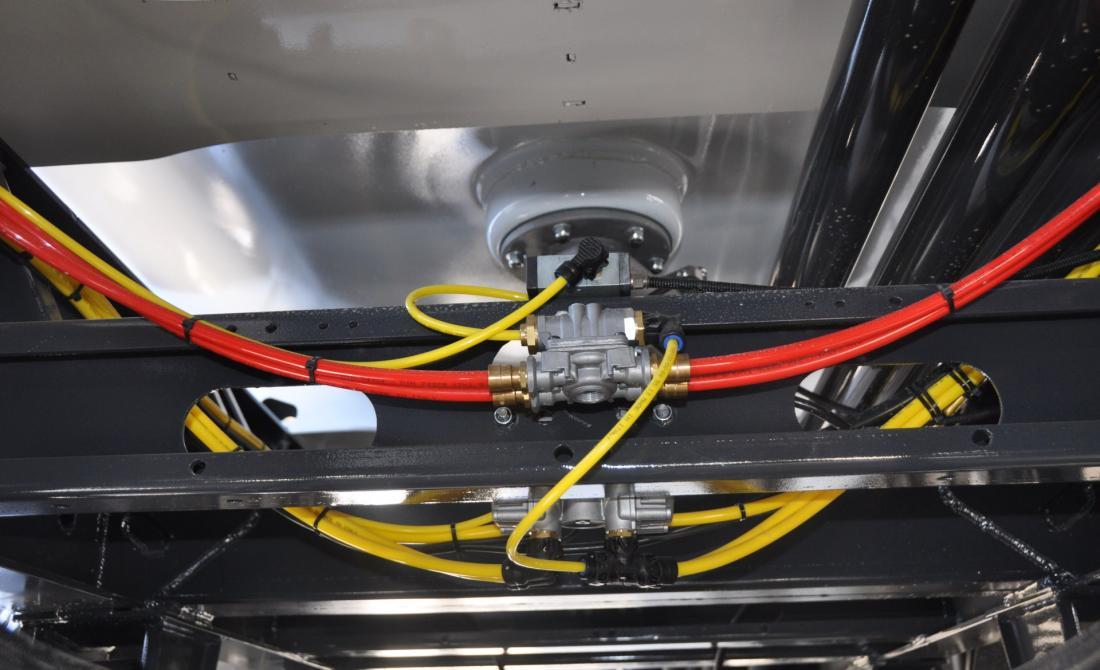

Specially designed alternative volume, discharge systems and equipment options; solves your business.

Functionality in the foreground

Designed specifically for the needs and expectations of users, with the option of heating and discharging system, where the transport temperature is protected, functionality is the foreground.

Performance needs source

Durable body structure, superior production technology and premium equipment, turn into the long lifetime to income.OUTSTANDING FEATURES

It provides ease of use, safety and automatically locks the brake system

Protect armatures against possible rollover and impact

The least number of (T) joints provide high strength and long life

Provides full discharge of the product at the bottom of the tank

Increases body strength at chassis joints, reduces tension effect, provides unity of body

Safe, smooth surface and unique body structure

Minimizes welding faults on the body due to tension and human factors are secures against impact

Provides surface gloss in varnish quality

Provides complete discharge without any liquid remaining in the tank body

Covers national and International up-to-date regulatory compliance

Prevents complexity on installation cables, provides serviceability